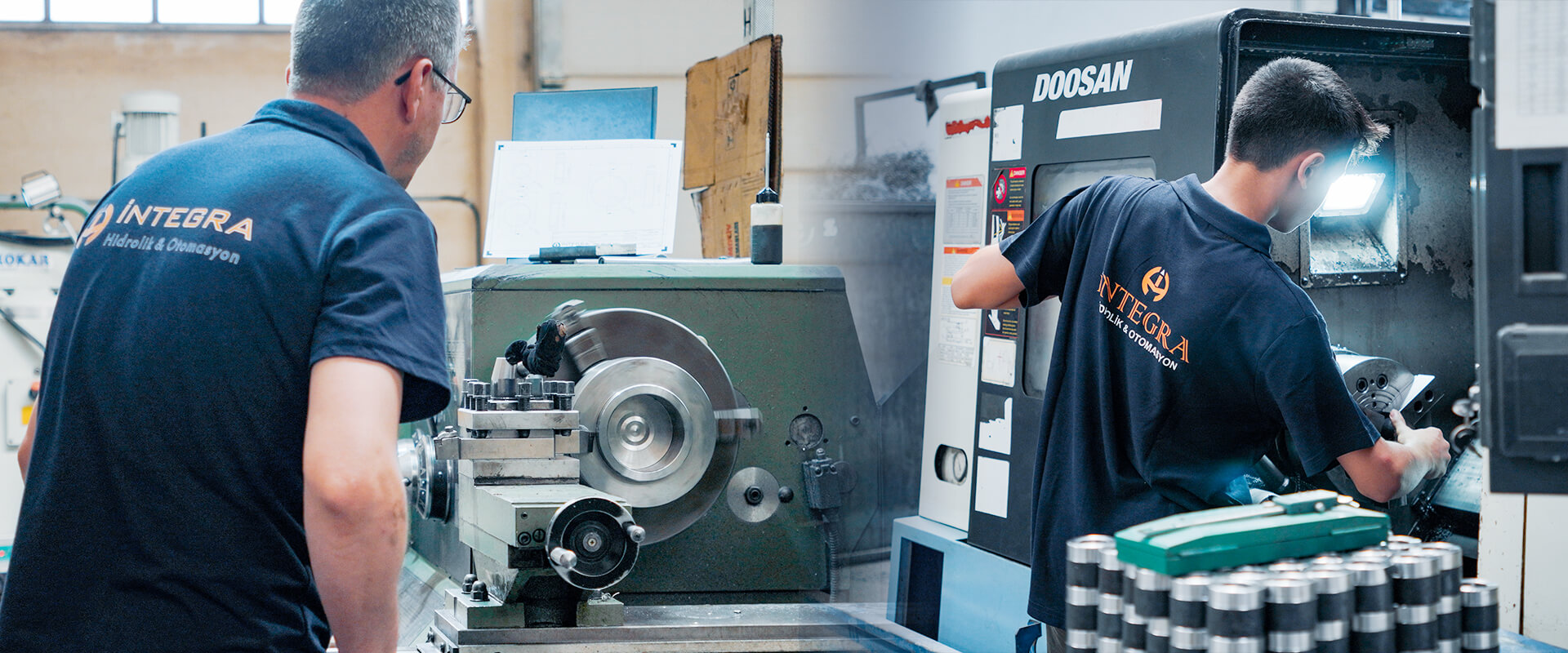

One of the key stages of our production process is the machining phase, which is extensively used, especially in hydraulic cylinder manufacturing. At this stage, parts are processed and shaped with the highest precision in accordance with the dimensions and tolerances defined during the project planning and design phases.

With the machining equipment available in our own workshop, each component is carefully processed, and critical parts used in hydraulic cylinders—such as pistons, gland caps, tubes, and chrome-plated rods—are prepared to deliver the required durability. As a result, the parts achieve a long-lasting, reliable, and high-performance structure.

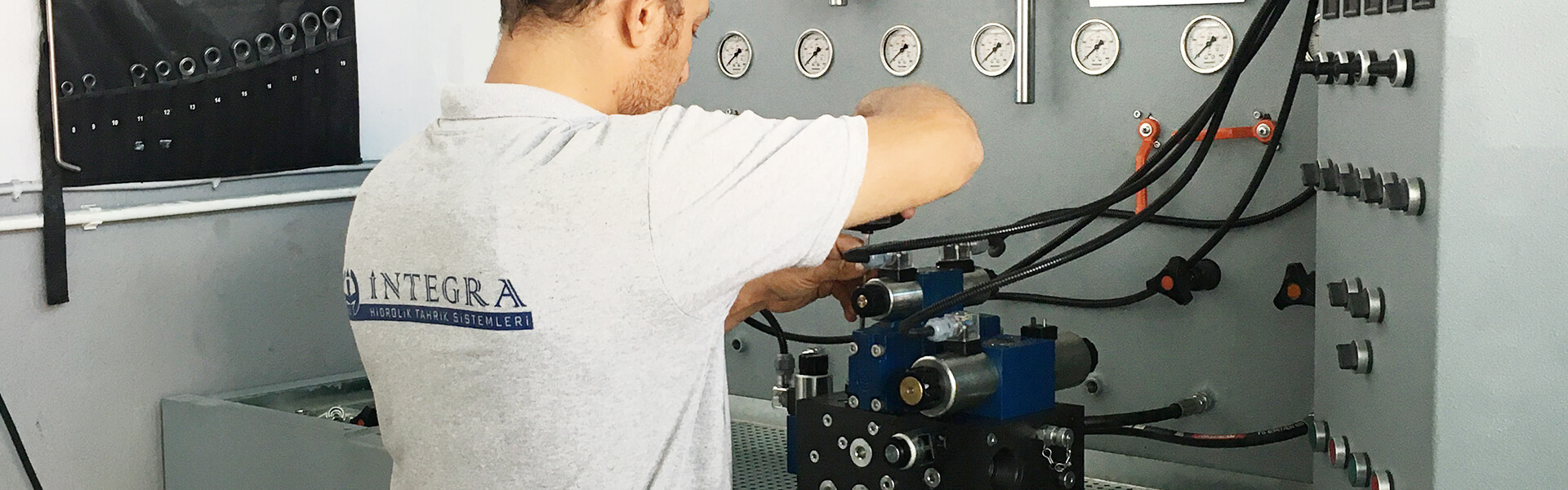

Supported by rigorous quality control procedures, the machining stage plays a vital role in ensuring the reliability and efficiency of hydraulic systems. In this way, we provide our customers with solutions that are not only technically flawless but also economically efficient.